Self-insulated block production line project in South Africa

Project Name

Self-insulated Block Production Line Project for South African Customers

Project Time

June 2025

Project Background

There is a growing demand for self-insulated blocks in the South African construction market. The customer plans to introduce an intelligent production line to improve product quality and production efficiency. Through on-site inspection and technology comparison, the customer focuses on equipment precision, mold adaptability and production stability, and finally chooses our solution.

Customer Needs

The customer's core needs include:

-

Produce 600×250×100/140/200mm multi-size blocks with mold size tolerance within 5mm.

-

High cutting precision, error less than 1mm, low waste rate, beautiful products without damage.

-

Convenient equipment operation, high degree of intelligence, support for long mold box and square mold box production.

-

High mold turnover rate, stable daily output to meet the requirements of efficient production.

-

Provide perfect architectural design program and technical training

Project Overview

This project is an intelligent self-insulation block production line, covering mixing, pouring, cutting and other key processes, adopting new high-speed cutting saw technology, supporting the production of multi-specification products and multi-purpose use of one machine, which significantly improves the production efficiency and product accuracy.

Project Highlights

-

High-precision cutting technology: cutting error is less than 1mm, low scrap rate and high product aesthetics.

-

Multi-specification production adaptation: support 600 x 250 x 100/140/200mm and other specifications of brick production, mold tolerance control within 5mm.

-

Intelligent operation experience: convenient operation of the equipment, high degree of intelligence, reducing manual intervention.

-

Efficient mold turnover: high mold turnover rate, stable daily output, improve production efficiency.

-

Multi-purpose advantage: support long mold box and square mold box production, to adapt to diversified order requirements.

Cooperation process

The company promotes the project in phases:

-

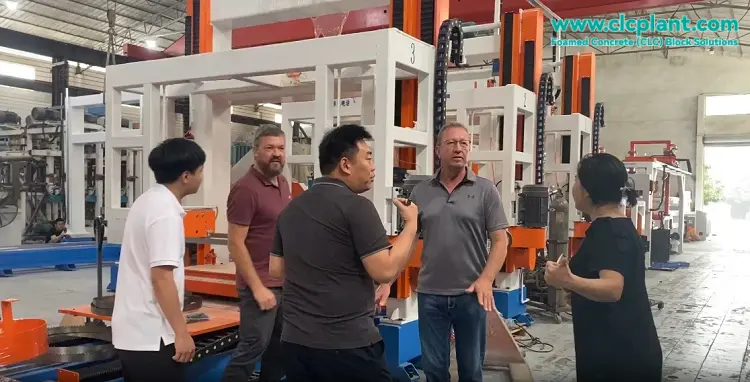

Factory visit and technical exchange: customers visit the production line, personally operate the cutting equipment, in-depth understanding of the details of the process.

-

Demand docking and program customization: Provide perfect architectural design and equipment configuration for customers' multi-specification production demand.

-

Equipment manufacturing and shipment: complete the production and testing of the equipment, and ship it to the customer's site on time.

-

Technical support and training: provide equipment installation and commissioning guidance and operation training to ensure that customers master the production technology.

Project Effect

The project is expected to realize the following results:

-

Meet the customer's demand for multi-specification and high-precision block production.

-

Cutting precision and product aesthetics are significantly improved, and the waste rate is reduced.

-

Improve production efficiency, stabilize daily output and optimize mold turnover rate.

-

Provide technical and equipment support for the customer to develop the South African market.

-

Lay the foundation for our company to deepen cooperation in the African market