Ceramsite Wall Panel Production Line Solution: Comprehensive Technology and Equipment for Leading Green Building Future

Under the wave of modernization and green transformation of construction industry, lightweight ceramic wall panels and blocks have become the mainstream new wall materials in the market. Our company integrates the international cutting-edge German CLC technology and inorganic nano enhancement process, and launches the fully automatic ceramic wall panel overall solution with leading technology and high return on investment, which provides building materials enterprises with the whole life cycle service from project planning, equipment configuration to production and operation.

I. Solution Core Advantages

1. High comprehensive investment benefits

-

Abundant policy dividends: the project is in line with the national comprehensive utilization of resources policy, enjoy tax breaks and waste subsidies, significantly reducing investment costs.

-

Low cost of raw materials: the project supports the use of industrial solid waste such as fly ash, coal gangue and recycled construction waste, and the comprehensive utilization rate of raw materials is ≥70%, which significantly saves the cost of raw material procurement.

-

Flexible investment options: provide large, medium and small capacity configuration (daily output of 100-1000 cubic meters), support batch investment, flexible expansion, reduce the initial investment threshold.

2. Green energy saving and environmental protection

-

Non-autoclave energy-saving maintenance: adopting self-heating circulation maintenance process, optional air heating system, comprehensive energy consumption ≤ 15kgce/t, much lower than the traditional autoclave process.

-

Near-zero emission of waste materials: real-time recycling of cutting waste materials, no emission of waste water and gas throughout the process, realizing green and clean production.

3. Excellent production and operation efficiency

-

High degree of automation: Intelligent numerical control of the whole line, support female workers to operate, low labor intensity, labor cost savings of more than 40%.

-

High mold turnover rate: optimize the mold design and cutting process, improve the efficiency of mold use and shorten the production cycle.

Second, the leading technical advantages

1. Intelligent control system

-

Adopting industrial-level intelligent numerical control system to realize digital and precise control of the whole process of mixing, foaming, mold injection and maintenance.

-

It is equipped with parameter memory, automatic correction, real-time monitoring and data tracing functions to ensure stable product quality.

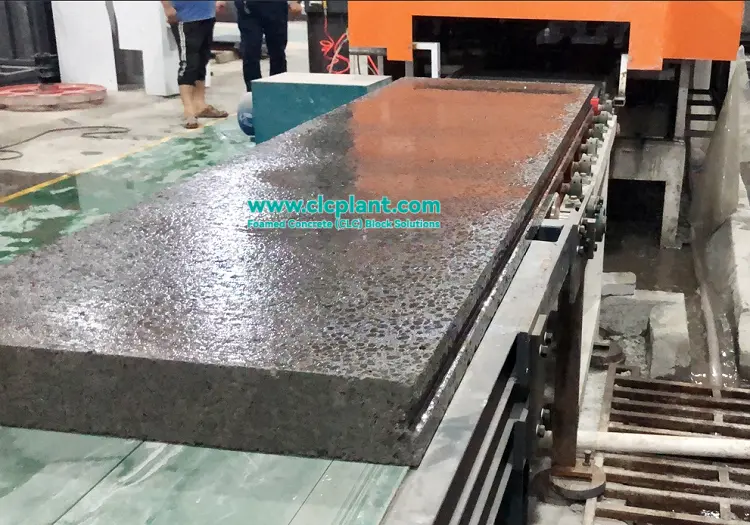

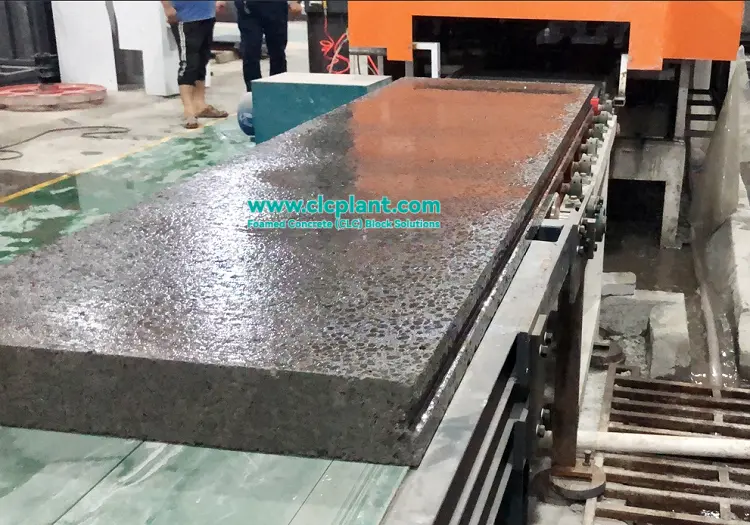

2. High-precision cutting technology

-

Core equipment ceramic wall panel cutting machine adopts multi-filament synchronous control technology, cutting precision error ≤ 1.0mm, product size consistency is excellent.

-

Support online wet cutting and online dry cutting process, to adapt to different strengths of the embryo, the surface is smooth and clean without secondary processing.

3. Flexible production process

-

One machine is multi-purpose, which can produce both lightweight wall panels (cement foam board, ALC board, EPS polystyrene granule board, etc.) and blocks (self-insulated blocks, ceramic granule blocks, aerated blocks, etc.).

-

Flexible adjustment of the formula and process parameters, easy to realize the product series switching, rapid response to changes in market demand.

Wide range of applications

The products produced by this production line have excellent performance and can meet a variety of construction application scenarios:

1. Assembly building

2. Public building projects

-

Widely used in schools, hospitals, office buildings and other public buildings with high requirements for sound insulation and fire protection, with fire resistance limit of 2-4 hours and sound insulation performance ≥ 44dB.

3. Residential and commercial buildings

-

It is used in the internal partition wall and external filler wall of residential commercial buildings, commercial complexes and other buildings, with both lightweight and high strength and heat preservation and energy-saving functions, and a single material can meet the building energy-saving standards.

4. Industrial buildings and remodeling projects

-

Applicable to industrial plants, warehousing facilities and old house renovation projects, reducing the building load by 20%-30%, while enhancing the building thermal insulation performance.

Successful cases

Case 1: a new building materials enterprise resource comprehensive utilization project

A new building materials enterprise introduced our full set of lightweight ceramic wallboard production line, making full use of the abundant local fly ash and construction waste as the main raw materials, not only significantly reduce the production cost, but also successfully evaluated as the provincial comprehensive utilization of resources demonstration project. Its products are listed as designated suppliers by many famous real estate enterprises for their precise size, stable performance and convenient installation, with excellent market feedback and investment recovery in the same year.

Case 2: Technical transformation and upgrading project of thermal insulation material factory

An insulation material manufacturer through the introduction of our production line program, in the absence of new plant area under the premise of successful product transformation and capacity enhancement. The production of self-insulating ceramic blocks are widely used in local public building projects, the energy-saving acceptance rate of 100%, reduce the overall production costs by more than 30%, market competitiveness has increased significantly, and become a regional green building materials benchmark enterprises.

V. Full technical support and service

Our company provides a full range of technical support:

-

Plant construction planning: provide complete plant layout and process flow design program (recommended plant size: width 20-60m, length 80-200m, height 6m or more).

-

Optimization of raw material ratio: Provide personalized formula solution according to the characteristics of local raw materials to ensure product quality and cost optimization.

-

Equipment installation and commissioning: professional team on-site installation and commissioning to ensure that the equipment quickly reach production.

-

Technical training: provide comprehensive training on production process and equipment operation and maintenance.

-

After-sales protection: establish a rapid response mechanism to provide original parts supply and continuous technical upgrading services.

Ceramic wall panel production line integrates advanced technology, environmental protection concept and economic benefits, which is the ideal choice for building materials enterprises to seize the green building market opportunity. We sincerely invite all industry colleagues to visit us and jointly create a better future for green building materials!