- Home

-

Products

Foam concrete block equipmentSelf-insulated block equipment

- Self-Insulating Block Cutting Machine

- Homogeneous Self-Insulating Block Production Equipment

- EPS Self-Insulating Block Production Equipment

- Composite Sandwich Self-insulating Block Production Equipment

- Polystyrene Granule Self-Insulating Block Production Equipment

- Homogeneous Panel Production Equipment

Lightweight partition wall board equipment- Partition Panel Cutting Machine

- Waterproof ALC Wall Panel Production Equipment

- Lightweight Partition Panel Production Equipment

- EPS Beads Partition Panel Production Equipment

- Foamed Cement Partition Panel Production Equipment

- Cutting type hollow wall panel production equipment

- Foam Concrete Wall Panel Production Equipment

- High-Precision Waterproof Partition Panel Production Equipment

- Permanent Formwork Production Line

- Fully Automatic Horizontal Wall Panel Production Line

Ceramic block equipmentCeramic wall panel equipment -

Solutions

CLC Solutions

- Foam concrete block production line solutions

- Self-Insulating Block Production Line Solution

- Ceramsite Wall Panel Production Line Solution

- Ceramsite Block Production Line Solution

- Lightweight Partition Panel Production Line Solution

- Industrial Waste Slag to Brick and Solid Waste Utilization Solution

- Construction and Demolition Waste to Brick and Comprehensive Utilization Solution

- Fly Ash Brick Manufacturing Solution

- Tailings-to-Bricks Solution

- Cases

- About Us

- Blog

- Contact Us

Menu

Foam concrete block equipment

Self-insulated block equipment

- Self-Insulating Block Cutting Machine

- Homogeneous Self-Insulating Block Production Equipment

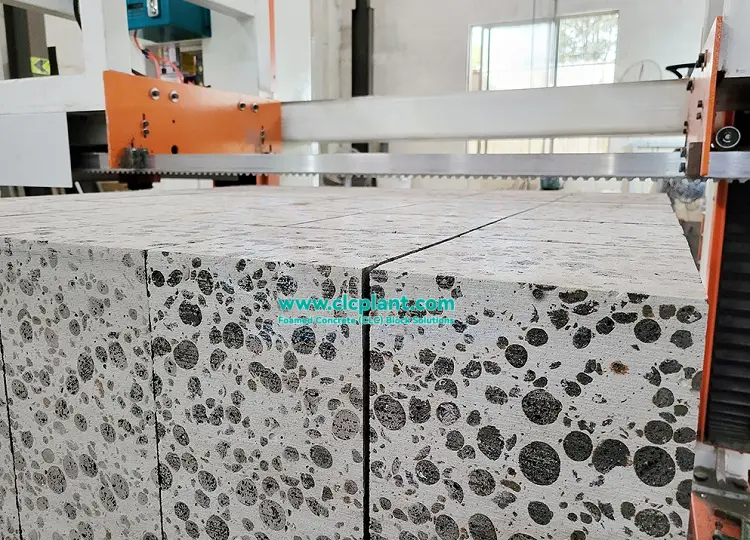

- EPS Self-Insulating Block Production Equipment

- Composite Sandwich Self-insulating Block Production Equipment

- Polystyrene Granule Self-Insulating Block Production Equipment

- Homogeneous Panel Production Equipment

Lightweight partition wall board equipment

- Partition Panel Cutting Machine

- Waterproof ALC Wall Panel Production Equipment

- Lightweight Partition Panel Production Equipment

- EPS Beads Partition Panel Production Equipment

- Foamed Cement Partition Panel Production Equipment

- Cutting type hollow wall panel production equipment

- Foam Concrete Wall Panel Production Equipment

- High-Precision Waterproof Partition Panel Production Equipment

- Permanent Formwork Production Line

- Fully Automatic Horizontal Wall Panel Production Line

Ceramic block equipment

Ceramic wall panel equipment

CLC Solutions

- Foam concrete block production line solutions

- Self-Insulating Block Production Line Solution

- Ceramsite Wall Panel Production Line Solution

- Ceramsite Block Production Line Solution

- Lightweight Partition Panel Production Line Solution

- Industrial Waste Slag to Brick and Solid Waste Utilization Solution

- Construction and Demolition Waste to Brick and Comprehensive Utilization Solution

- Fly Ash Brick Manufacturing Solution

- Tailings-to-Bricks Solution